|

Equipment in our Labs

Want to Learn more? Just click on the hyperlinks!

Plasma Reactors

Below is a dual mode, microwave (MW) and low frequency (LF) plasma reactor [PLASMAtech, Erlanger, KY]. It can be operated in a batch or continuous

|

|

| PlasmaTech Reactor |

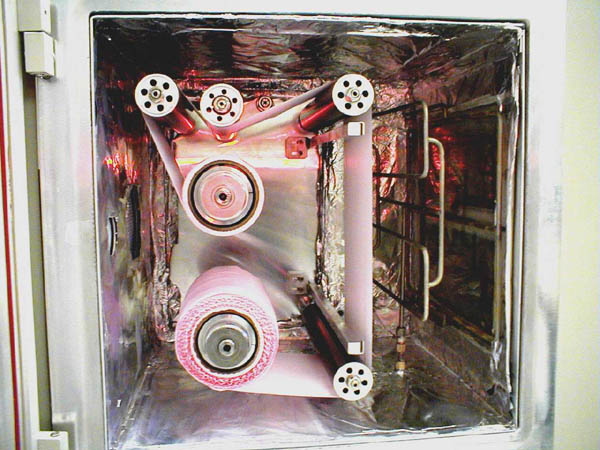

View of PlasmaTech Reactor Chamber |

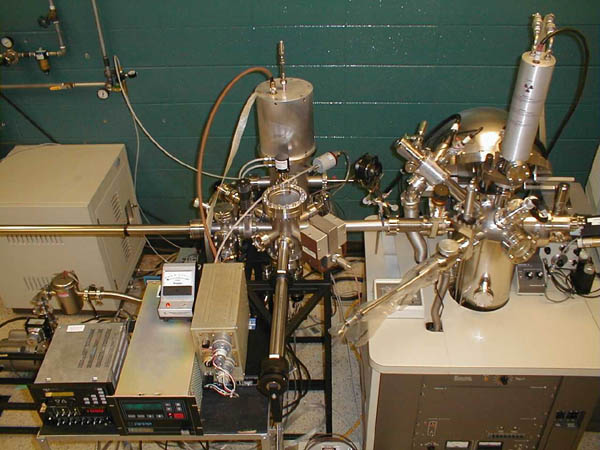

Recently, a time-of-flight mass spectrometer (TOF-MS), residual gas analyzer (RGA), and optical emission spectrometer (OES) were added to this reactor, as shown below:

Time-of-Flight Mass Spectrometer and Residual Gas Analyzer

We also have the capability to do IR and XPS of plasma treated surfaces in-situ (without exposing the samples to atmosphere. This equipment is very important to the study of the structure of interfaces, as exposure to atmosphere alters the chemistry.

|

|

| Reactor with In-situ IR |

Reactor with In-situ XPS |

We have two more plasma reactors used to deposit films, etch and functionalize surfaces shown below:

|

|

| Microwave Power Plasma Reactor |

Radio Frequency Power Plasma Reactor |

Spectroscopic Characterization Tools

We use many different characterization tools to investigate the surfaces that we engineer. Infrared and Raman spectroscopy enables us to investigate the chemical bonding present in a material. XPS allows us to determine the chemical composition of a surface (top 10 nm). The variable angle spectroscopic ellipsometer is also useful to determine film thickness and refractive index.

|

| Nicolet Infrared and Raman Spectrometer, with reflection and attenuated total reflection accessories. |

|

| Variable angle spectroscopic ellipsometer (VASE) |

Other Equipment

|

| Polymer injection molder |

|

| Contact angle goniometer and tensiometer |

|

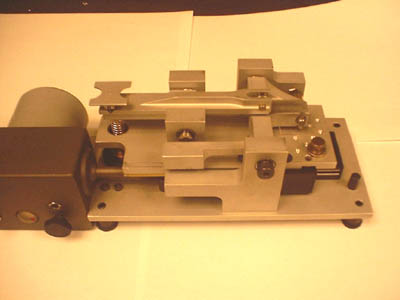

| Scratch Tester |

We also have use of all the facilities at the Materials Characterization Center.

|